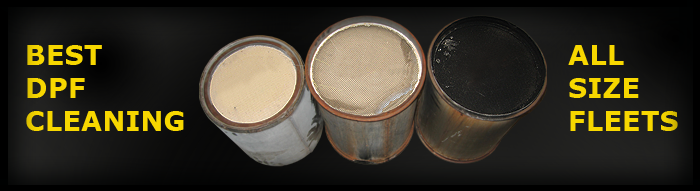

DPF and DOC Cleaning

Diesel Particulate Filters (DPF) require regular maintenance to insure proper and efficient operations (view OEM Cleaning Intervals). Using the Industry's leading DPF Cleaning system, FSX, Filter Service and Supply can restore your DPF to near new condition. Having a DPF Cleaned during routine maintenance will result in:

- Increased Fuel Economy

- Increased Performance & Horsepower

- Less Downtime

- Fewer Regenerations

- Longer DPF Life

- Lower Maintenance Cost

- Maximized Cleaning Intervals

Inspections and Testing

Filter Service & Supply inspects and tests the filter at every step of the DPF cleaning process. When we are finished processing the DPF we know the exact condition of the filter and have absolute confidence and knowledge of the level of recovery. Complete documentation is provided with each filter we clean. You are going to know the condition of each filter before and after it is cleaned. Cleaning results are shared with you and can be compared with historical recovery levels for the filter.

Quality Control

FSX equipment and the DPF cleaning process has been subjected to rigorous testing by engineering teams from many major engine OEMs. These tests determined that the FSX equipment, process and thermal cleaning programs provide the best DPF cleaning available without damaging the ceramic substrate, wash-coats or packing materials. The FSX thermal programs adhere to all filter manufacturer specifications for cleaning.

Turn-Around

Filter Service & Supply typically performs the Stage 1 Pneumatic Cleaning on an incoming filter within 8 business hours of arrival. If the filter needs a Stage 2 Thermal Cleaning the process time is about 12 hours

Typical turn around times:

Stage 1 Pneumatic Cleaning - 2 to 8 hours

Stage 1 Pneumatic Cleaning plus Stage 2 Thermal Cleaning - 24 hours